How to connect spark plug wires to the distributor? To connect spark plug wires to the distributor correctly, follow these steps:

Step 1: Identify the Firing Order

Step 2: Remove Old Spark Plug Wires

Step 3: Install New Spark Plug Wires

Step 4: Connect Wires to the Distributor

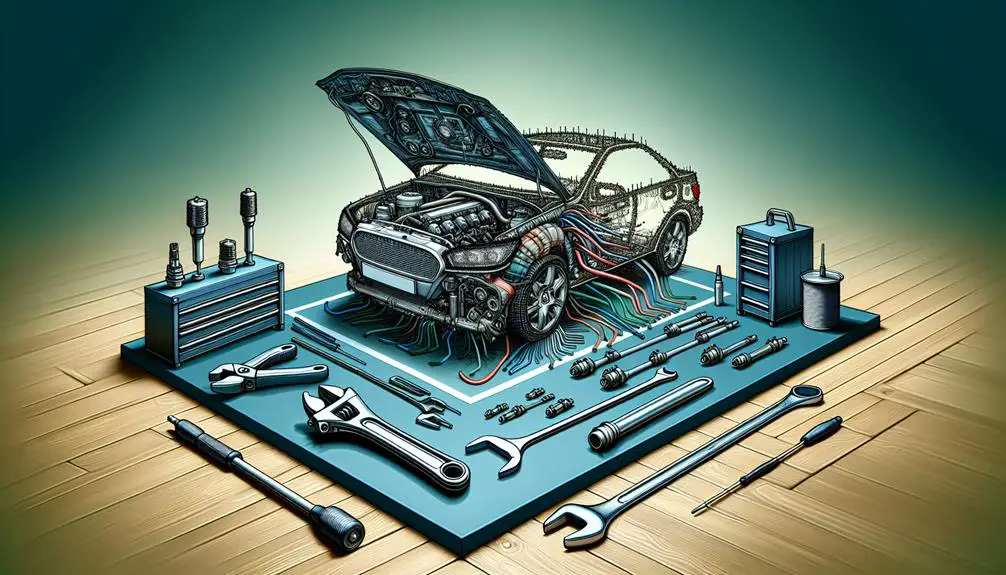

Tools and Materials Needed

Before you begin connecting spark plug wires to the distributor, you’ll need to gather a few necessary tools and materials. This step is important for ensuring the job is done correctly and safely. Without the right equipment, you’re setting yourself up for potential issues down the road.

Here’s what you’ll need to pay attention to:

- Spark Plug Wire Set: This seems obvious, but make sure you’ve got the correct set for your vehicle’s make and model. Each wire will connect a spark plug to the distributor, facilitating the necessary electrical connection to start your engine.

- Wire Crimping Tool: To secure the spark plug leads to the distributor, you’ll need a reliable wire crimping tool. This is important for attaching the metal connectors at the ends of the wires securely to the spark plugs and distributor.

- Dielectric Grease: Applying a small amount of dielectric grease to both ends of each spark plug wire before installation can prevent voltage leakage and corrosion. This is a pro tip that can extend the life of your spark plug wires.

Preparing for Installation

To begin, make sure your vehicle’s engine is cool to the touch. Working on a hot engine increases the risk of burns and other injuries. Once you’ve confirmed the engine is cool, follow these steps to prepare for installation:

- Clean the Work Area: Make sure the area around the distributor cap and spark plugs is clean and free of debris. A clean workspace will prevent dirt from entering the engine components and ensure a clearer view of the installation area.

- Organize Your Tools and Materials: Lay out all the tools and new spark plug wires you gathered from the previous step. Having everything within easy reach will streamline the installation process.

- Identify the Firing Order: Before you start, it’s essential to know the engine’s firing order. This information is often found in the vehicle’s service manual. Understanding the firing order is essential for correctly connecting the spark plug wires to the distributor.

Step-by-Step Guide to Connecting Spark Plug Wires to the Distributor

Step 1: Identifying the Firing Order

To accurately connect spark plug wires to the distributor, you’ll need to identify the engine’s firing order. This initial step is critical in the procedure to link ignition cabling to the distributor. It guarantees that each spark plug fires in the correct sequence, optimizing engine performance and efficiency.

You can typically find the firing order in your vehicle’s service manual or stamped on the engine itself.

Comprehending the steps to couple spark transmitting cords to the distributor starts with this fundamental knowledge. Without the correct firing order, your engine may run poorly, or not at all.

It’s the blueprint that guides you in connecting each spark plug wire to its corresponding terminal on the distributor cap. This precision ensures your engine runs smoothly, highlighting the importance of this primary step.

Step 2: Removing Old Spark Plug Wires

Before you connect new spark plug wires to the distributor, you’ll need to carefully remove the old ones. Removing old spark plug wires is a crucial process, but it requires attention to detail to avoid damaging the distributor or the engine.

Start by gently twisting each wire at the boot to loosen it from the spark plug. Then, pull the wire away from the plug.

Repeat this process for the distributor end, being cautious not to pull the wires too hard which might damage the connections.

It’s crucial to keep track of which wire goes where; this will make it easier when you’re ready to fasten spark plug leads to the distributor. Remember, patience is key to safely removing the wires without causing any damage.

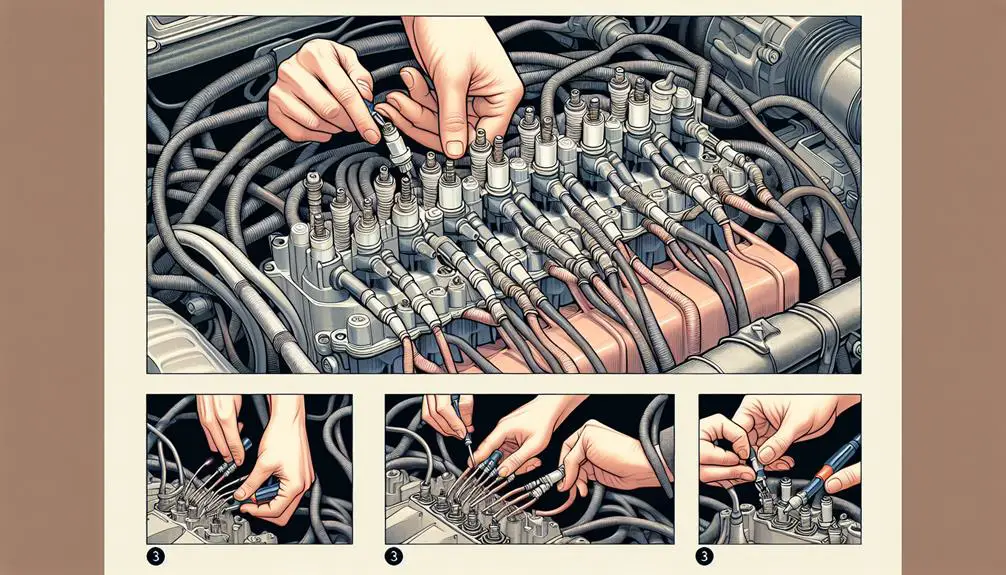

Step 3: Installing New Spark Plug Wires

After carefully removing the old spark plug wires, you’re ready to install the new ones and connect them to the distributor. Begin by ensuring you’ve got the correct set of wires for your engine. Each wire varies in length to precisely match its specific spark plug location.

Start with the longest cable, which usually connects to the spark plug farthest from the distributor. Gently push the connector onto the spark plug until you hear a click, indicating it’s securely attached. Don’t force it; a proper fit shouldn’t require excessive pressure.

Repeat this process for each spark plug, working your way to the shortest cable. You’re not just replacing parts; you’re connecting ignition wires in the engine, ensuring each affixes correctly to foster smooth operation.

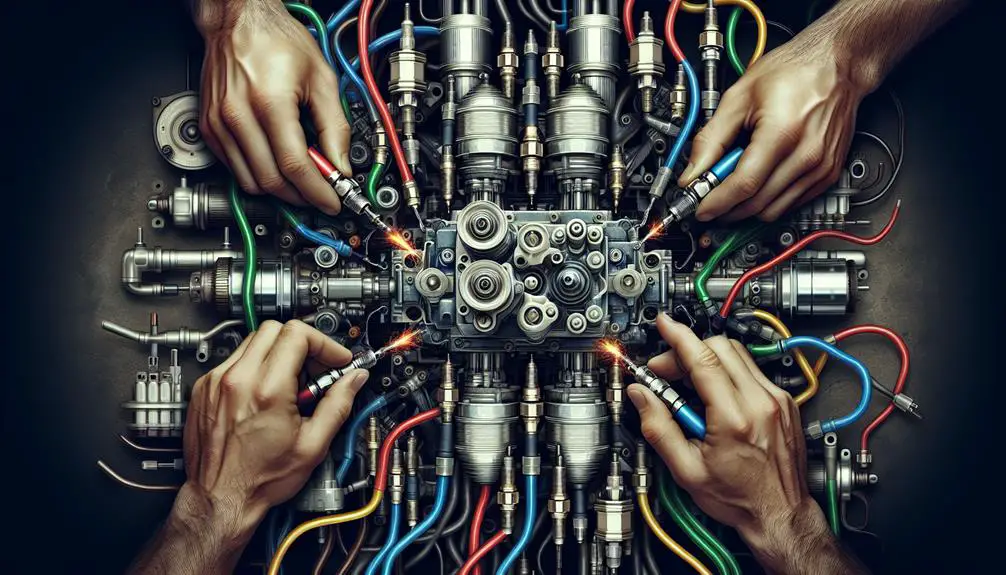

Step 4: Connecting Wires to the Distributor

Once you’ve securely attached the spark plug wires to their respective plugs, it’s time to connect them to the distributor. This step is important for making sure your engine runs smoothly.

Each spark plug wire has a specific position on the distributor cap that corresponds to the firing order of your engine. You’ll find the distributor cap on top of the distributor.

To attach ignition wires to the distributor, gently push the boot of each wire onto the correct terminal on the distributor cap until you hear a click, indicating a secure connection. Make sure to organize the wires to prevent them from crossing over or tangling, as this can cause misfires.

Secure spark conductor lines to the distributor systematically, double-checking each connection for firmness. This precise arrangement guarantees top engine performance and efficiency.

Troubleshooting Common Issues

Addressing common issues can streamline the process of connecting spark plug wires to the distributor, securing your engine runs smoothly. If you’re facing difficulties, it’s likely because of improper tethering of the electrical discharge wire to the distributor. This misstep can cause misfires or poor engine performance. Carefully review your connections, making sure each wire securely snaps into place.

Running spark plug strings to the emission regulator requires precision. Misrouting can lead to crossfire and engine misfires. Make sure each wire is correctly aligned and connected to its corresponding cylinder. This meticulous attention to detail will prevent common pitfalls and boost your engine’s efficiency. Remember, a well-executed connection fosters top-notch engine performance.

Maintenance Tips for Spark Plug Wires and Distributors

Maintaining your spark plug wires and distributor is crucial for guaranteeing your vehicle’s peak performance. Beyond the basic steps of connecting spark plug wires to the distributor, regular maintenance can greatly extend the life of these components and improve your car’s efficiency.

Here are a few tricks and tips to keep everything in top shape:

Regularly Inspect and Clean Your Components: Check your spark plug wires and distributor for signs of wear or damage, such as cracks or corrosion. Cleaning them with a soft cloth and appropriate cleaner can prevent buildup that might disrupt the electrical flow.

Ensure Secure Connections: Tricks for securing igniter wires to dispenser and guiding electrical discharge filaments to current overseer are fundamental. Make sure the spark plug wires are firmly attached to both the spark plugs and the distributor. A loose connection can lead to misfires and reduced vehicle performance.

Replace Worn Parts Promptly: Spark plug wires and distributors don’t last forever. If you notice any damage or if your vehicle starts to run roughly, it might be time for replacements. Using high-quality replacement parts can make a significant difference in your vehicle’s performance.

Wrapping Up

Connecting spark plug wires to the distributor is a crucial skill for maintaining your vehicle’s ignition system.

If you do the steps we talked about in this guide, your engine will work really well and won’t waste energy.

Remember these key takeaways:

- Always work on a cool engine to avoid burns.

- Label your wires before disconnecting to maintain the correct firing order.

- Clean the distributor cap and inspect for any damage before reconnecting.

- Ensure each wire is securely connected to both the distributor cap and spark plug.

- Double-check your work to prevent misfires and engine performance issues.