Understanding the difference between your vehicle’s starter motor and alternator is essential for diagnosing electrical problems. While both components are crucial to your car’s electrical system, they serve completely different functions, operate at different times, and convert energy in opposite directions.

What Is a Starter Motor?

A starter motor is an electric motor that initiates engine operation by converting electrical energy from the battery into mechanical energy. When you turn your key or push the start button, the starter engages with the engine’s flywheel, physically rotating the crankshaft to begin the combustion process.

The starter motor consists of several key components working together:

- Solenoid: Acts as a high-current electrical switch

- Armature: The rotating part that generates mechanical force

- Field coils: Create the magnetic field for the armature

- Brushes: Transfer electrical current to the armature

- Pinion gear: Engages with the engine’s flywheel

- Housing: Contains and protects all components

This powerful motor draws significant current (typically 100-400 amps) from the battery for a brief period, creating enough mechanical force to overcome engine compression and friction to initiate rotation.

What Is an Alternator?

An alternator is an electrical generator that converts mechanical energy from the engine into electrical energy. Once the engine is running, the alternator:

- Recharges the battery that was partially depleted during starting

- Powers all electrical components while the vehicle is running

- Maintains consistent voltage throughout the electrical system

The alternator is driven by a belt connected to the engine’s crankshaft. As the engine runs, this mechanical rotation spins the alternator’s rotor, creating a magnetic field that induces electrical current in the stator windings. This alternating current is then converted to direct current by diodes and regulated to maintain proper voltage (typically 13.5-14.8 volts).

Unlike the starter motor which only works briefly, the alternator operates continuously whenever the engine is running, ensuring a steady supply of electrical power to all vehicle systems.

Key Functional Differences Between Starters and Alternators

The fundamental starter motor vs alternator function differences include:

- Energy conversion direction:

- Starter: Converts electrical energy to mechanical energy

- Alternator: Converts mechanical energy to electrical energy

- Operating time:

- Starter: Works briefly (1-3 seconds) during engine ignition

- Alternator: Functions continuously while the engine runs

- Power relationship:

- Starter: Consumes electrical power (high current draw)

- Alternator: Produces electrical power (steady output)

- Connection to engine:

- Starter: Engages mechanically with the flywheel/flexplate

- Alternator: Connected via belt to the crankshaft pulley

- Current characteristics:

- Starter: Uses direct current (DC) at high amperage

- Alternator: Produces alternating current (AC) that’s converted to DC

These distinct roles create a complementary relationship where each component performs a specialized function at different stages of vehicle operation.

When Each Component Works in Your Vehicle’s Operation

The starter and alternator operate at different times in your vehicle’s operational cycle:

Starter motor operation:

- You turn the key to the “start” position or press the start button

- Current flows from the battery to the starter solenoid

- The solenoid engages the pinion gear with the flywheel

- The starter motor cranks the engine until it starts

- Once the engine is running, the starter disengages completely

Alternator operation:

- The engine starts running after successful cranking

- The drive belt rotates the alternator pulley

- The alternator begins generating electricity

- The voltage regulator maintains proper output (13.5-14.8V)

- The alternator powers all electrical systems and recharges the battery

- It continues operating until the engine is turned off

This sequential relationship highlights why a vehicle with a dead battery might start with a jump but die shortly after if the alternator isn’t functioning properly.

Starter Motor Components and Operation

The starter motor system consists of several critical components:

- Starter solenoid: An electromagnetic switch that performs two functions:

- Pushes the pinion gear forward to engage with the flywheel

- Closes the circuit to allow high current flow to the starter motor

- Armature: The rotating part consisting of wire windings around an iron core that creates mechanical motion when electrified

- Field coils: Generate the magnetic field that interacts with the armature

- Brushes: Graphite contacts that transfer electrical current to the commutator

- Commutator: A segmented copper cylinder that reverses current direction to maintain rotation

- Pinion gear: Engages with the engine’s flywheel/flexplate to transfer rotational force

- Overrunning clutch: Prevents damage when the engine starts by allowing the pinion to rotate faster than the starter motor

When activated, the solenoid pushes the pinion gear forward to mesh with the flywheel while simultaneously closing the circuit. Current flows through the field coils and armature, creating electromagnetic force that rotates the armature at high speed. This rotation is transferred through the pinion gear to the engine’s flywheel, turning the crankshaft until combustion begins.

Alternator Components and Function

The alternator consists of these essential components:

- Rotor: A spinning electromagnet powered by the battery through slip rings and brushes

- Stator: Stationary copper windings surrounding the rotor where electrical current is induced

- Diode rectifier bridge: Converts alternating current (AC) produced in the stator to direct current (DC) for vehicle use

- Voltage regulator: Controls field current to maintain consistent output voltage regardless of engine speed or electrical load

- Pulley: Connects to the engine via a belt to receive mechanical input

- Bearings: Support the rotor shaft and allow smooth rotation

- Housing: Contains and protects all components while providing cooling

When the engine runs, the belt turns the alternator pulley, spinning the rotor. The rotating magnetic field from the rotor induces alternating current in the stator windings. This AC current passes through the diode rectifier bridge, converting it to DC. The voltage regulator continuously adjusts the field current to the rotor, maintaining steady output voltage regardless of engine speed or electrical demand.

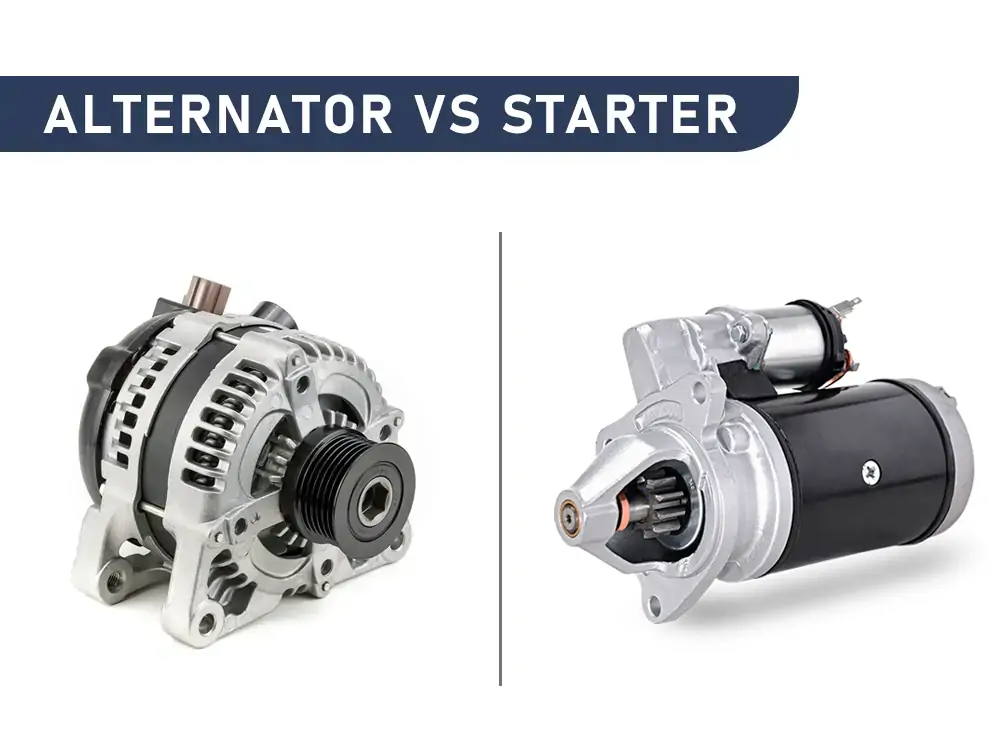

How to Identify Each Component Under Your Hood

Identifying the starter motor location in car and alternator position:

Starter motor:

- Typically cylindrical, about 6-8 inches long

- Usually located low on the engine, where it meets the transmission

- Connected to a large cable directly from the battery

- Often has a smaller wire harness connection for the control circuit

- In front-wheel-drive vehicles: Often accessed from above, near the firewall

- In rear-wheel-drive vehicles: Usually mounted between the engine block and transmission

Alternator:

- Typically has a distinctive pulley and cooling vents

- Located at the front of the engine, driven by the serpentine belt

- Connected to several electrical wires, including a main charging cable

- Usually mounted higher on the engine than the starter

- Often has an aluminum housing with visible cooling fins

The starter is generally more difficult to access as it’s typically mounted lower on the engine, while the alternator is more visible and accessible from the top of the engine compartment.

Symptoms of a Failing Starter Motor

Common starter motor symptoms include:

- Clicking noise when turning key: The solenoid is activating but the motor isn’t turning

- Grinding sound during starting: Indicates worn pinion gear or flywheel teeth

- Starter motor not engaging: You hear the solenoid click but no cranking occurs

- Intermittent starting issues: Sometimes works, sometimes doesn’t

- Starter motor clicking noise repeatedly: Often indicates insufficient power reaching the starter

- Slow cranking: Engine turns over more slowly than normal

- Smoke or burning smell: Indicates a starter motor overheating issue

- No response when turning key: Complete starter failure or electrical connection problem

These symptoms often develop gradually, though complete failure can occur suddenly. Many drivers first notice starting becoming less reliable before complete failure occurs.

Symptoms of a Failing Alternator

Key indicators of alternator problems include:

- Battery warning light illuminated: The most direct indicator

- Dimming or brightening headlights: Fluctuating voltage causes noticeable changes

- Multiple electrical systems failing: Power windows, radio, and lights may malfunction

- Battery drains quickly after charging: The alternator isn’t recharging the battery

- Engine stalling while driving: Insufficient power to the ignition system

- Burning rubber smell: Often from a slipping alternator belt

- Whining or grinding noise: Indicates bearing failure or internal damage

- Difficulty starting after running: Battery hasn’t been recharged properly

Unlike starter issues which primarily affect starting, alternator problems typically cause progressive electrical system deterioration while driving, eventually leading to complete electrical failure and engine shutdown.

Testing Your Starter Motor Without Special Tools

To test your starter without specialized equipment:

- Listen test: Turn the key and listen carefully:

- Click with no cranking: Likely starter motor or solenoid issue

- No sound at all: Check battery connections or starter circuit

- Grinding noise: Damaged pinion gear or flywheel

- Tap test: With the key in start position, gently tap the starter body with a hammer handle:

- If the engine starts after tapping, the starter has internal issues

- This temporarily frees stuck components or helps brushes make contact

- Visual inspection:

- Check for corrosion or loose connections

- Look for physical damage or oil leaks on the starter

- Verify the starter mounting bolts are tight

- Bypass test (for advanced DIYers):

- Use a screwdriver to bridge between the large terminal on the solenoid and the starter body

- If the starter cranks, the solenoid control circuit is faulty

These methods can help determine if the starter is the problem before investing in replacement parts or professional diagnosis.

Testing Your Alternator Without Special Tools

Simple ways to check alternator function:

- Headlight brightness test:

- Start the engine and turn on headlights

- Rev the engine slightly

- If lights brighten as RPM increases, the alternator is working

- Dimming or no change may indicate alternator problems

- Battery behavior after jump start:

- If your car starts with a jump but dies soon after, the alternator likely isn’t charging

- Disconnection test (use with caution):

- With engine running at idle, disconnect the negative battery terminal

- If the engine dies immediately, the alternator isn’t producing power

- Note: This test can damage sensitive electronics in modern vehicles

- Dashboard light observation:

- Turn key to “on” position (before starting)

- Battery light should illuminate

- Start engine – light should turn off

- If light stays on while running, alternator may not be charging

These tests provide basic diagnostic information without specialized tools, though a proper voltage test with a multimeter is more reliable.

Common Misconceptions About Starters and Alternators

Several myths and misconceptions exist about these components:

- Myth: Alternators charge batteries when the engine is off

Reality: Alternators only produce power when the engine is running - Myth: A bad starter affects engine performance while driving

Reality: Once the engine is running, the starter is completely disengaged - Myth: Alternators and starters typically fail together

Reality: They usually fail independently due to different wear patterns - Myth: Jump starting always fixes alternator problems

Reality: Jump starting only helps with battery issues, not alternator failures - Myth: Tapping a starter is a permanent fix

Reality: While tapping may temporarily work, it indicates internal damage requiring replacement - Myth: Alternators last the lifetime of the vehicle

Reality: The average lifespan of a starter motor and alternator is typically 7-10 years or 100,000-150,000 miles

Understanding these distinctions helps prevent misdiagnosis and unnecessary repairs.

The Relationship Between Your Battery, Starter, and Alternator

These three components form an interdependent electrical system:

- Battery: Stores electrical energy and provides initial power for starting

- Starter: Uses battery power to crank the engine

- Alternator: Recharges the battery and powers electrical systems while running

This cycle creates a dependency where:

- Without a charged battery, the starter can’t function

- Without a working starter, the engine can’t run to power the alternator

- Without a functioning alternator, the battery eventually depletes

This relationship explains why diagnosing electrical problems can be challenging – a symptom in one component may actually be caused by a failure in another.

Can a Bad Alternator Damage Your Starter?

A failing alternator can indirectly affect your starter:

- When an alternator fails to properly charge the battery, the battery becomes depleted

- A consistently undercharged battery forces the starter to operate with insufficient voltage

- Low voltage causes the starter to draw higher amperage to compensate

- This increased current generates excessive heat in the starter windings

- Over time, this heat damages the starter’s internal components

Additionally, voltage irregularities from a failing alternator can damage sensitive electronic components in the starter circuit. While not an immediate effect, chronic alternator problems will eventually contribute to premature starter failure.

Can a Bad Starter Affect Your Alternator?

Generally, a bad starter has minimal direct impact on alternator function since they operate at different times. However, there are indirect connections:

- Repeated failed starting attempts can drain the battery severely

- A deeply discharged battery places additional load on the alternator

- This increased charging demand can accelerate alternator wear

Additionally, starter motor wiring issues that cause excessive current draw can potentially damage shared electrical system components. However, in most cases, starter problems remain isolated from alternator function once the vehicle is running.

Replacement Costs Compared: Starter vs Alternator

Typical cost ranges for replacement:

Starter motor repair cost:

- Parts: $80-$350 depending on vehicle make/model

- Labor: $70-$400 (1-2 hours typically)

- Total: $150-$750

Alternator replacement:

- Parts: $150-$500 depending on vehicle make/model

- Labor: $70-$300 (1-2 hours typically)

- Total: $220-$800

Factors affecting cost:

- Vehicle make/model (luxury and European vehicles typically cost more)

- OEM vs. aftermarket parts

- Accessibility (some vehicles require significant disassembly)

- Rebuilt vs. new components (rebuilt units are typically 20-40% less expensive)

Generally, alternators tend to be slightly more expensive than starters, though this varies by vehicle. Both components are significant repairs but are far less expensive than engine or transmission work.

Lifespan Expectations: How Long Should Each Last?

Typical durability expectations:

How long do starter motors last:

- Average: 100,000-150,000 miles or 7-10 years

- Factors affecting lifespan:

- Number of starting cycles (short trips cause more wear)

- Climate conditions (extreme temperatures reduce lifespan)

- Quality of electrical system (voltage irregularities cause premature failure)

- Manufacturing quality (OEM vs. aftermarket)

Alternator lifespan:

- Average: 80,000-150,000 miles or 7-10 years

- Factors affecting lifespan:

- Electrical load demands (aftermarket audio systems, additional lighting)

- Environmental exposure (water, salt, heat)

- Belt condition (slipping belts damage bearings)

- Driving conditions (stop-and-go traffic increases wear)

Modern vehicles tend to have longer-lasting electrical components than older models, though increased electronic complexity can introduce more potential failure points.

DIY Replacement Difficulty: Starter vs Alternator

Comparing the DIY challenge level:

Starter replacement:

- Difficulty: Moderate to difficult

- Accessibility: Often challenging, may require lifting vehicle

- Tools needed: Basic socket set, wrenches, possibly jack and stands

- Time required: 1-3 hours depending on vehicle

- Challenges: Limited workspace, heavy component, awkward positioning

Alternator replacement:

- Difficulty: Easy to moderate

- Accessibility: Usually visible and accessible from engine top

- Tools needed: Basic socket set, wrenches, belt tools

- Time required: 1-2 hours depending on vehicle

- Challenges: Belt tensioning, multiple electrical connections

For most vehicles, alternator replacement is generally more DIY-friendly due to better accessibility and simpler mounting. Following a DIY starter replacement guide can make the job manageable for those with basic mechanical skills, though some vehicles require significant disassembly for starter access.

When to Repair vs Replace Each Component

Decision guidelines for repair versus replacement:

Starter considerations:

- Repair if: Solenoid issues, minor brush wear, or simple wiring problems

- Replace if: Armature damage, extensive internal wear, or housing damage

- Rebuilding viable when: Core is in good condition and rebuild kits are available

- Starter solenoid replacement alone may be sufficient if the motor portion is still good

Alternator considerations:

- Repair if: Brush wear, simple regulator issues, or minor bearing noise

- Replace if: Stator/rotor damage, diode failure, or significant bearing wear

- Rebuilding viable when: Housing and shaft are in good condition

- Often more cost-effective to replace the entire unit in modern vehicles

For both components, the availability of quality rebuilt units often makes complete replacement more economical than repair, especially when labor costs for diagnosis and repair are considered.

Preventative Maintenance to Extend Starter and Alternator Life

Practices for preventing starter motor failure and alternator issues:

Starter maintenance:

- Keep battery connections clean and tight

- Maintain proper battery charge

- Avoid excessive cranking (no more than 10 seconds at a time)

- Address unusual noises promptly

- Keep the starter clean and free from oil contamination

- Ensure proper engine ground connections

Alternator maintenance:

- Inspect and replace belts before they show excessive wear

- Keep the alternator clean and free from oil/fluid contamination

- Maintain proper belt tension

- Address electrical issues promptly to prevent overloading

- Avoid extreme electrical loads when idling

- Keep battery connections clean to ensure proper charging

Regular electrical system checks during routine maintenance can identify potential issues before they cause component failure, significantly extending service life.

People Also Ask

Can a car run with a bad starter?

Yes, a car can run with a bad starter. Once the engine is running, the starter is completely disengaged and has no role in continued operation. However, you won’t be able to restart the engine if you turn it off.

Can a car run with a bad alternator?

A car can run temporarily with a bad alternator, but only until the battery charge is depleted. Depending on battery condition and electrical demands, this might be anywhere from a few minutes to about 30 miles of driving before complete electrical failure.

What happens when an alternator fails while driving?

When an alternator fails while driving, the vehicle initially runs on battery power alone. You’ll typically see the battery warning light illuminate, followed by progressive electrical system failures (dimming lights, failing accessories), and eventually, the engine will stall when the battery can no longer power the ignition system.

Does the alternator charge the battery that powers the starter?

Yes, the alternator charges the battery that powers the starter. This creates a cycle where the battery provides power to start the engine, then the alternator recharges the battery while the engine runs, ensuring it’s ready for the next start.

Can a bad starter drain your battery?

Yes, a bad starter can drain your battery. A damaged starter may develop internal shorts that create a parasitic drain, slowly depleting the battery when the vehicle is off. A starter that’s struggling to operate also draws excessive current, potentially draining the battery during starting attempts.

How do you tell if it’s your starter or alternator that’s bad?

To distinguish between alternator vs starter problems: If your car won’t start and you hear clicking or nothing happens when turning the key, it’s likely a starter issue. If your car starts but dies while running, dashboard lights dim while driving, or the battery warning light is on, it’s probably an alternator problem.

Do alternators fail suddenly or gradually?

Alternators typically fail gradually, showing symptoms like dimming lights, battery warning lights, or intermittent electrical issues before complete failure. However, internal component failures (like diodes or voltage regulators) can sometimes cause sudden failure without warning.

Which is more expensive to replace, a starter or alternator?

Alternators are typically slightly more expensive to replace than starters, though costs vary by vehicle. On average, alternator replacement costs $220-$800, while starter replacement ranges from $150-$750, including parts and labor.

Can jumping a car damage the alternator?

Jumping a car correctly rarely damages the alternator. However, improper jump starting (reverse polarity, voltage spikes) can damage the alternator’s diodes and voltage regulator. Always follow proper jump starting procedures to protect electrical components.

How often should starters and alternators be replaced?

Starters and alternators don’t have scheduled replacement intervals and typically last 7-10 years or 100,000-150,000 miles. Replace them when they show symptoms of failure rather than as preventative maintenance.